Project

Process Simulation and techno-economic Assessment of NOx-to-Ammonia in Ammonia powered Container Ships

This work was carried out as part of a semester project under the supervision of Margarita Athanasia Charalambous in the research group of Prof. Dr. Gonzalo Guillén Gosalbez at ETH Zurich.

Although the cargo ship is one of the most efficient methods of transporting goods, this industry is still responsible for 3% of global CO2 emissions purely due to its size. Accordingly, alternative fuels, such as ammonia or methanol, can potentially reduce these emissions. Specifically, ammonia with its comparatively easy handling and high energy density has great potential here. The problem with ammonia, however, is that burning it releases nitrogen oxides (NOx), which indirectly contribute to climate change through the formation of N2O. The aim of this project is therefore to use the software "Aspen Plus V11" to investigate whether it makes sense to incorporate a NOx-to-ammonia (NTA) process for this purpose.

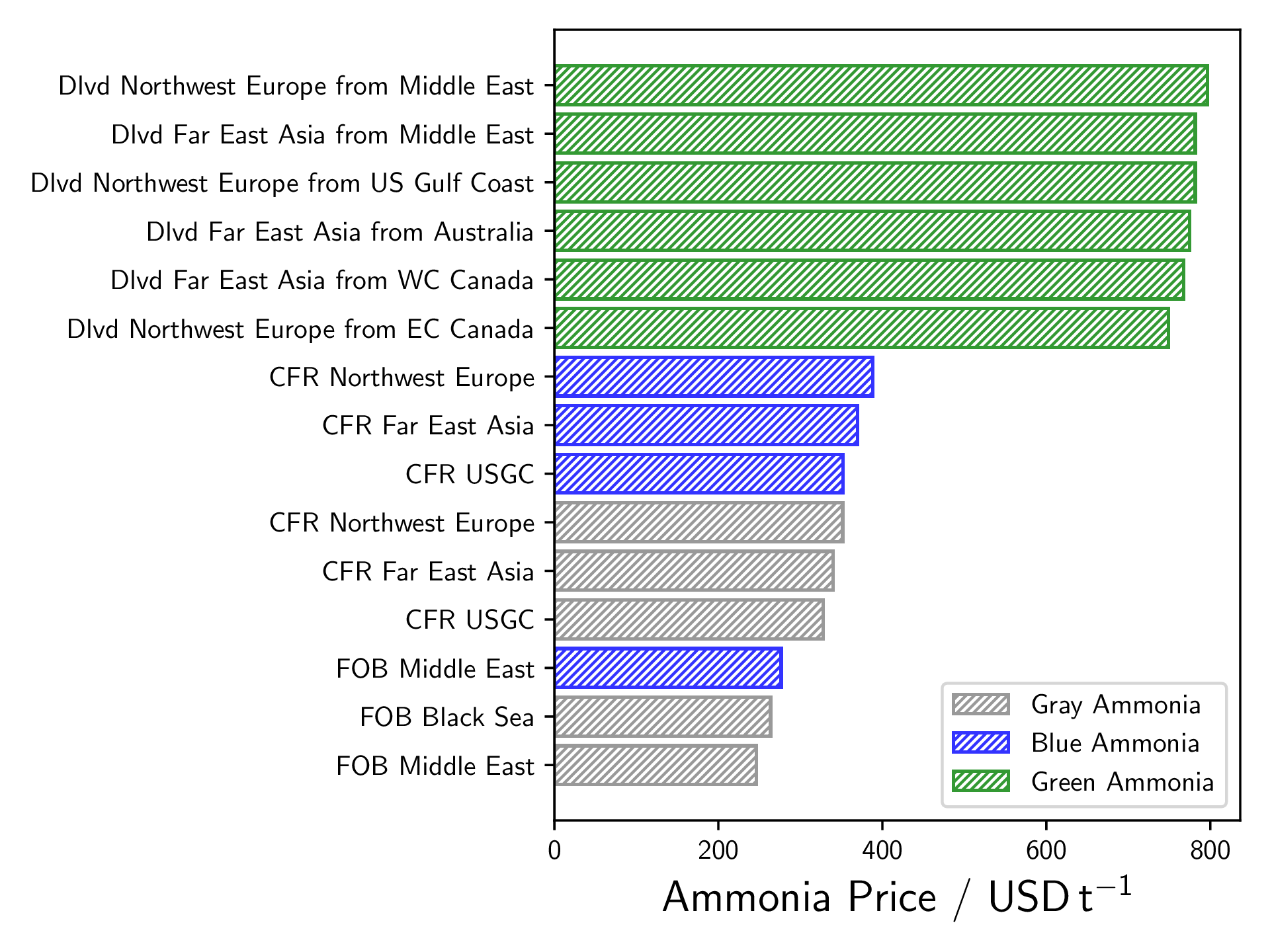

For all results, three ammonia cases were compared with "Business as Usual" (diesel) because the price and CO2 emissions vary depending on the production process. Gray ammonia is produced from nitrogen and hydrogen via the Haber-Bosch process, with the hydrogen being produced from methane and water via steam reforming and water gas shift. This process emits one mole of CO2 for each mole of hydrogen. Blue ammonia is produced in the same way, but 85% of the CO2 is captured and processed using Carbon Capture and Storage. Green ammonia uses hydrogen from water electrolysis using green electricity. The prices for these ammonia sources are compared in Fig. 1

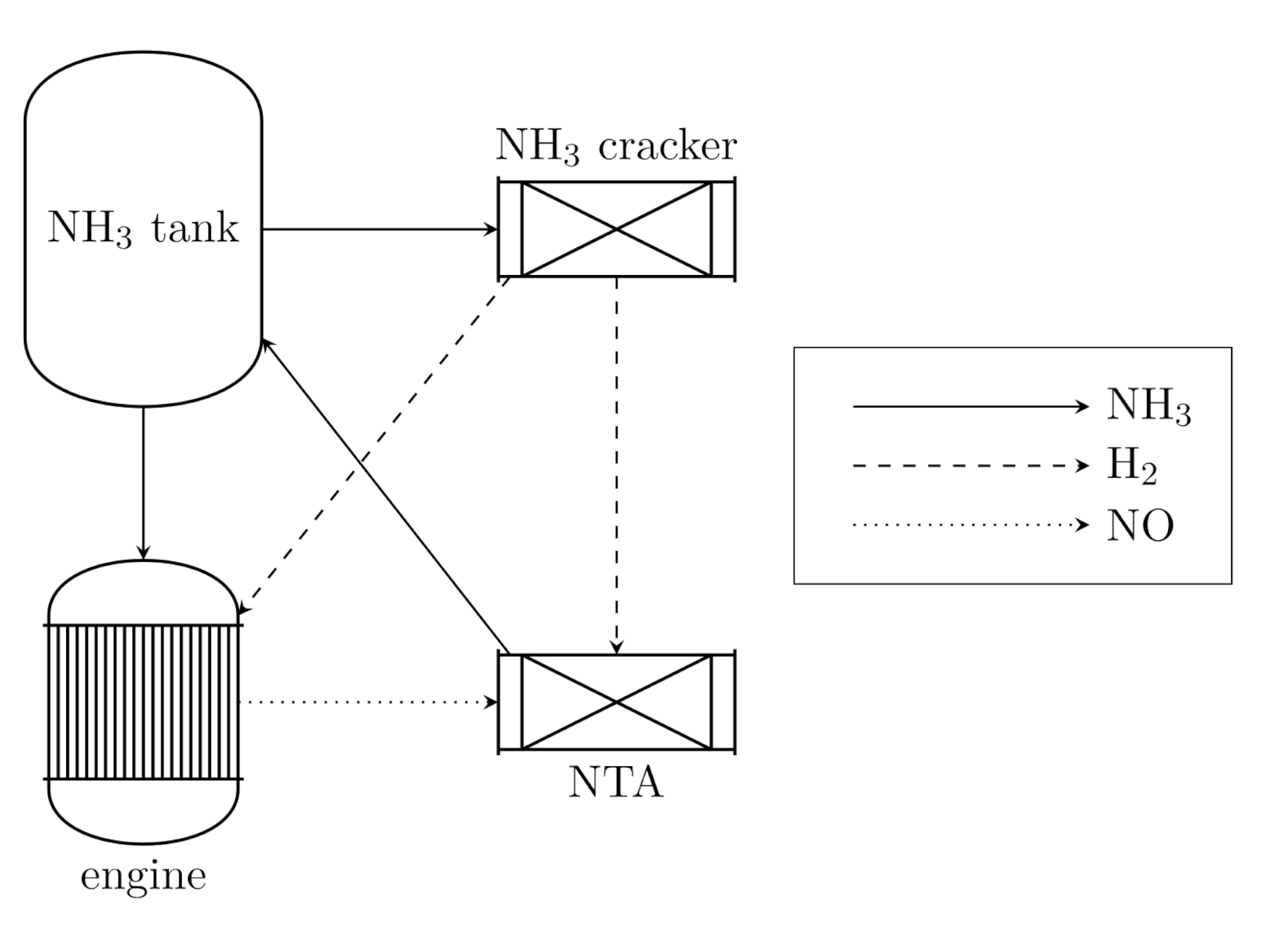

The idea behind this process is to react the nitrogen oxide produced during combustion with hydrogen back to ammonia and water. The hydrogen for this is produced from ammonia in a cracker (see Fig. 2). This can then be separated from the combustion products in a separation process and reused as fuel. The results were then used to evaluate whether the NTA process is worthwhile from both a financial and an ecological point of view.

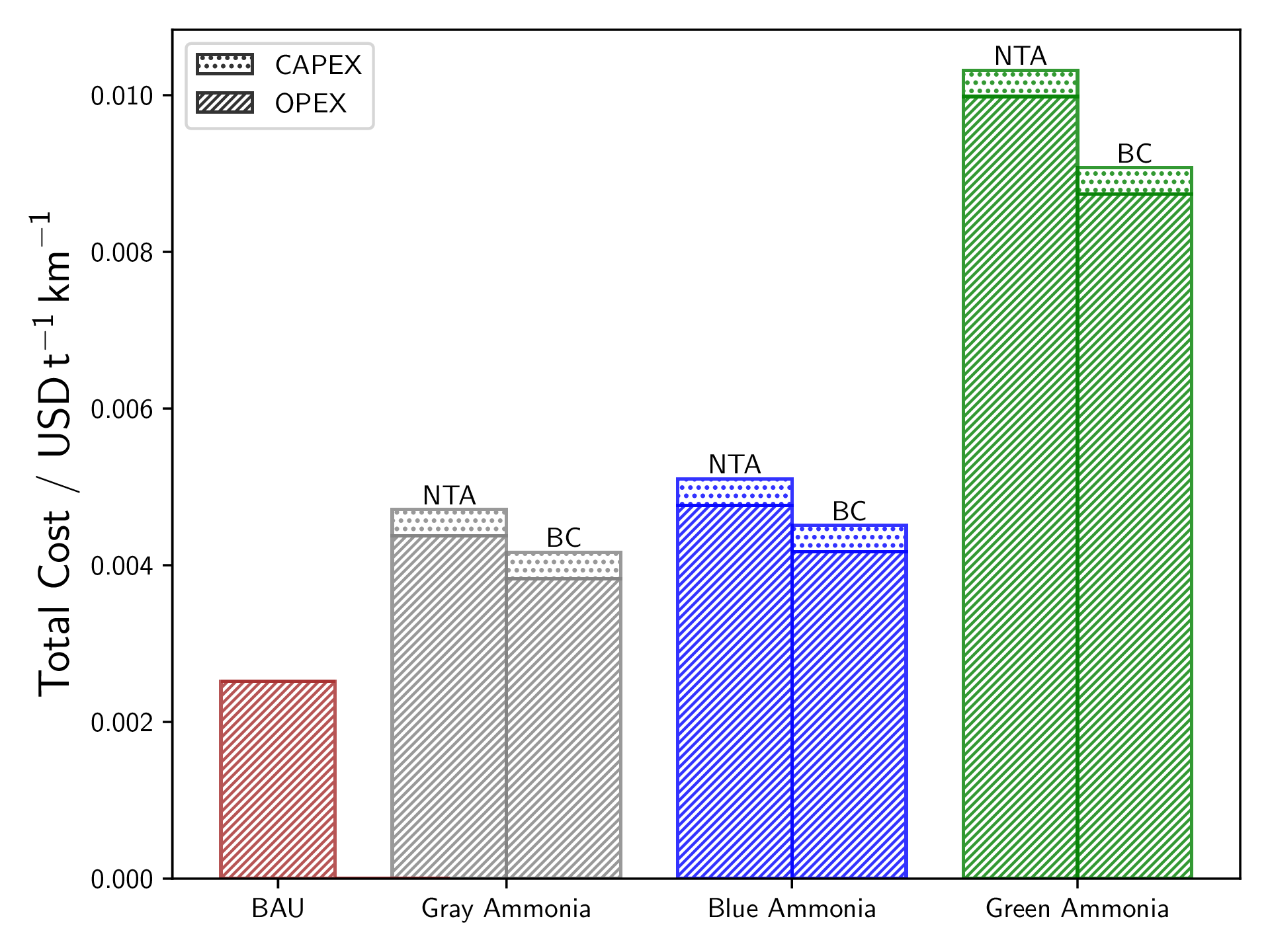

For the economic evaluation, a distinction must first be made between one-off costs for equipment (Capital Expenditure, CAPEX) and ongoing costs (Operating Expenditure, OPEX). The CAPEX is amortized over a lifetime of 15 years and then compared annually with the OPEX. Fig. 3 shows that in this case the OPEX, effectively the fuel costs, clearly outweigh the costs for an ammonia ship compared to a diesel ship (business as usual, BAU), as expected. The reason for this is that, although ammonia has a lower price per kilogram than diesel, the fuel consumption for ammonia is much higher than for diesel because we also have to feed the NTA reactor with hydrogen from ammonia.

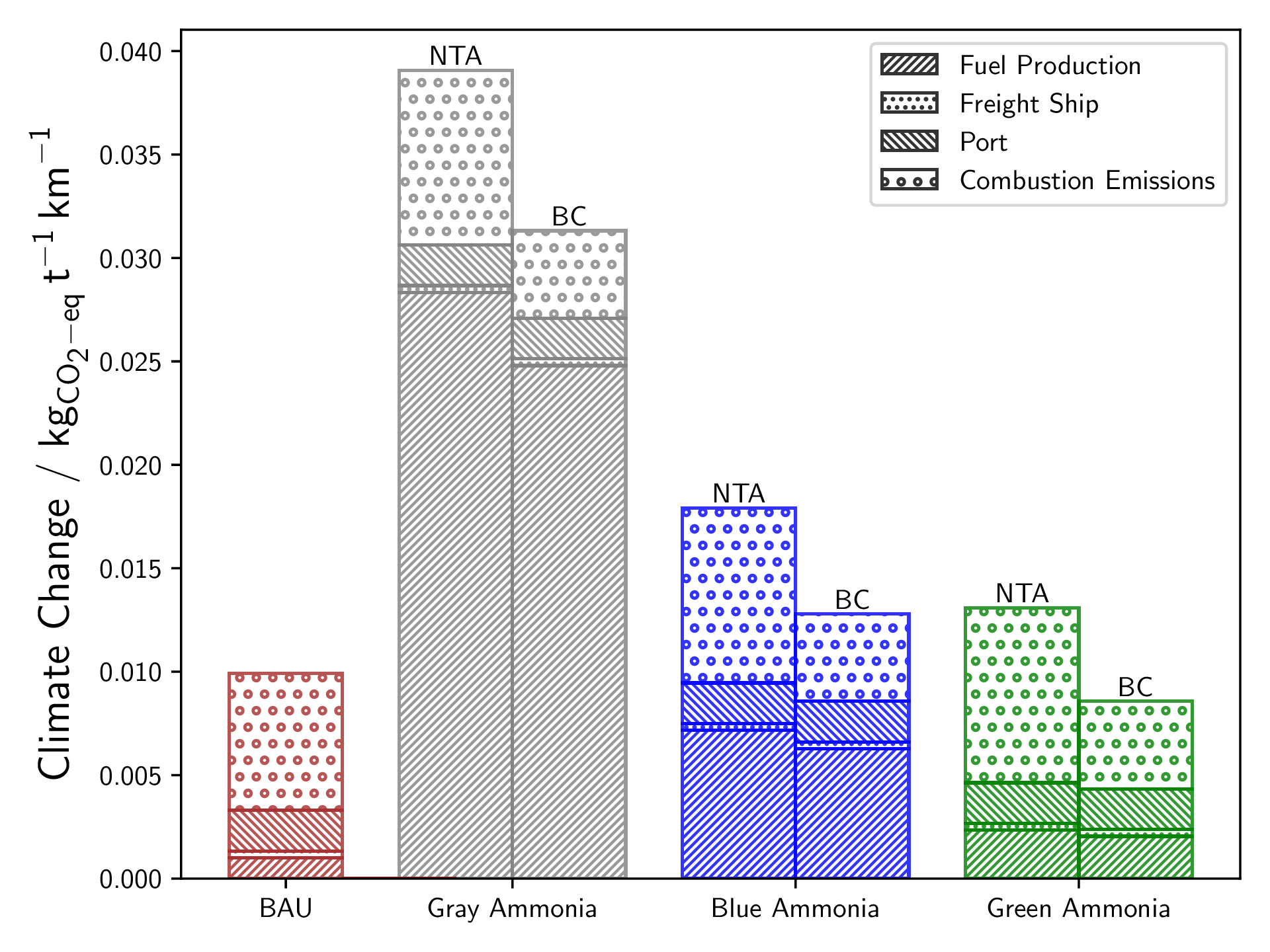

The evaluation of the life cycle assessment can be seen in Fig. 4. Here the effects on climate change of ammonia and diesel are compared. Here, the greenhouse effect of nitrogen oxide (NO) was estimated from the literature, although NO only has an indirect influence on climate change. This, combined with the very high fuel consumption of ammonia and the only 90% efficiency (i.e. 10% of the NO is released into the atmosphere) of the NTA process, leads to the results shown in Fig. 4.

It can be summarized that with the parameters from this project, an ammonia ship is not yet worthwhile. However, this could change in the future with a higher efficiency of the NTA process and a different hydrogen source.